The mantra of successful cannabis companies is consistency, consistency, consistency.

Whether it’s a cannabis strain, vape cartridge, or edible, businesses strive to give their customers the exact same experience. Every. Single. Time.

One surefire way for companies to achieve consistency is to adhere to good manufacturing practices (GMPs), which also ensure that goods are safe for the consumer. In conventional industries, GMPs cover all aspects of the production process, including the premises, materials, equipment, storage, record keeping, staff training, hygiene, protocol for handling complaints, and product development.

Does the cannabis industry have GMPs?

The FDA has established guidelines for manufacturing related to food, pharmaceuticals, and supplements, but because cannabis is still illegal at the federal level, none of the agencies that would develop GMP guidelines have done so. That’s forcing state lawmakers and business owners to operate in the rapidly changing industry without uniform guidance.

Still, many states have implemented regulations that are close to GMPs. This comes close to solving the problem for single-state operators, but companies that operate in multiple states are left to navigate regulations that vary across jurisdictions.

“The trend of requiring GMP certification is going to happen more and more as more states come on line because it’s an easier option for a regulated body to monitor,” said Kim Stuck, founder and CEO of Allay Consulting, a Colorado and Oregon-based compliance strategy and services provider that serves the hemp and cannabis industries nationwide. “Most governments right now are short staffed.”

GMPs and the global cannabis market

As cannabis becomes a global business, GMPs will be even more important. Since the World Health Organization (WHO) adopted GMPs in 1968, more than 100 countries have incorporated them into their national medicine laws. Many more countries have used WHO’s provisions and approach in defining their own national GMP requirements.

“Cannabis companies should be prepared for this because good manufacturing practices are necessary if we want to continue bringing credibility to the industry and if we want cannabis to be treated like any other mainstream industry,” said Justin Brandt, a partner in the Arizona-based cannabis law firm Bianchi & Brandt. “Right now, operators are taking a piecemeal approach, and they need guidance on how to get there.”

How to prepare for GMP requirements in the cannabis industry

A good place for companies to start preparing for GMP requirements is by hiring a consultant who can help them establish standard operating procedures (SOPs) and help bring their operations as close to compliance with the practices followed in a similar industry, whether it’s agriculture or food production.

“It’s the next step in the evolution of normalizing cannabis,” Brandt said.

“You adapt or you die. The sooner you get a head start on it, the better off you’ll be. Federal legalization is an inevitability, and it doesn’t hurt to be prepared.”

If the goal is to ensure consistency and repeatability of a finished product, there are a few universal truths for what should be included in a good system, Brandt said. First, Every GMP needs to have proper documentation. Second, every company that implements a GMP system must ensure its workforce is trained and educated on those processes. And finally, bringing on a quality-assurance specialist or other quality-control talent can help provide structure and accountability to GMP SOPs and ensure a high product standard.

“Every step of the process should be verifiable according to the particular SOP in place,” Brandt said. “Having a process or system in place is useless if your workforce isn’t trained on what to do.”

How cannabis GMPs can help companies scale up

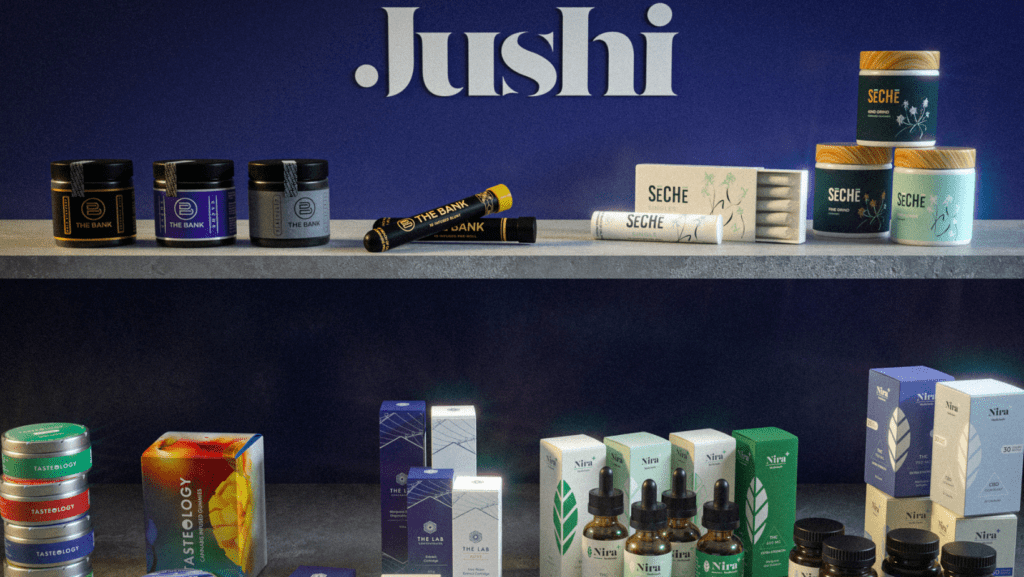

One company that’s implemented GMPs from the beginning is Florida-based Jushi Holdings. Jushi’s buildings and processes have been designed so that the MSO’s processes are consistent — no matter where it’s producing its products.

“Having that standardization and repeatable and replicable process and procedures to create products that are going to have the same effect in each state we operate in is super imperative,” said Trent Woloveck, the company’s chief commercial director.

Third-party testing to verify what’s in a company’s products is required in most states where cannabis is legal and is likely to go a long way to attracting new consumers to the industry, Woloveck said. Testing also is one way to compete with the illicit market that is prevalent in the US today.

“That’s going to be a major differentiator for us as we start to scale and take market share away from the illicit market,” Woloveck said. “If somebody can purchase an eighth of flower for $25 on the illicit market and pay $30 for regulated, they’re going to feel much more comfortable with that $30 because of GMP-certified growing, manufacturing, and processing procedures.”

For Colorado-based edible maker Wana Brands, GMPs start with the ingredients. The company works with suppliers that also operate under GMP standards, so it knows it’s getting high-quality ingredients.

“Once they enter the facility, you need to have a team dedicated to sanitation and tracking raw material lot numbers so you know what went where,” said Michael Kramer, Wana’s food safety and compliance manager.

That means tracking and tagging every batch of ingredients from the time they’re received to the time they are sent to shipping. Wana, which has a four-member quality team, tracks everything it uses both internally and through METRC, Colorado’s Marijuana Enforcement Tracking Reporting and Compliance system.

“Once the product leaves your facility, the focus shifts to taking customer complaints and comments seriously,” Kramer said. “We don’t have to do that very often, so we’re lucky there.”

Kramer said that as the country moves toward federal legalization, having GMP processes already in place will put it ahead of the game, although that’s not why the company adheres to them.

“At Wana, these programs are in place to protect consumers — we want people to trust Wana gummies, and it helps consumers know what they’re going to get,” Kramer said. “As we look toward legalization, it will help us be more agile and quick to respond. We won’t have to play catch-up.”

Agrify, which sells computer controlled vertical farming units for cannabis, is helping many marijuana companies achieve their GMP goals. The company’s systems incorporate many GMP characteristics into the cultivation process, including climate control, light intensity, and irrigation.

“What we’re starting to see is that no longer does cannabis just sell itself,” said Rob McEvoy, Agrify’s vice president of customer success. “GMP promises a guarantee to ensure they can capture the long-term values of cleanliness, safety, and efficacy on a consistent purchase-by-purchase basis. It makes their products shine above the very noisy retail shelf space that they’re operating out of.”

2 thoughts on “GMPs, MSOs, and the future of the cannabis industry”

Pingback: Good Manufacturing Practices in Cannabis | Apex Trading

Pingback: BDSA Brand Insights: Is “true” brand loyalty coming to legal cannabis? - MJ Brand Insights